Our side yard fence was physically falling apart, which meant that we were using metal rods to hold it upright and boards fell off every time the wind kicked up. A board would fall down, we’d screw it back up, the posts would slump over and we would prop them up, seriously, we put up with this crap for almost three years.

The cause of the deterioration was the rotted off bottoms of the support posts and the poorly chosen nails that secured the boards in place. Both issues equaled ghetto failing fence.

We couldn’t afford to replace the entire thing, so in order to keep things budget friendly, we reused almost all of the weathered fence boards and just replaced the support structure.

That meant that we had to carefully disassemble the fence and install new 4×4″ posts. We called Carpenter Craig to come help since he just finished a big mending fencing project at his new house and had the skills and tools to help.

Digging post holes by hand? BLOWS.

Of course we hand dug all the holes, centered our posts and then Quikreted them into place.

Then the horizontal supports went into place. We just followed the design of the rest of the fence, nothing to exciting design wise.

Removing all of the boards (and all the nails) also blew. We had to be really careful since we needed the wood to be reinstalled. Four nails a board + a couple hundred boards is a whole lot of tetanus to avoid. Filthy dirty tedious work.

After all the wood was prepped, we strung a string line from the existing fence top to keep everything even and cohesive. Totally rocket science. Then we started screwing up the fence boards with some deck screws. Totally tedious.

One of our curious neighbors came over to watch. He tends to come over and watch while we do projects…and drink our beer. Lend a hand dude!

Speaking of neighbors…

So, the cat hoarding guy who lives next door (who shares the fence with us) didn’t want to chip in $100 to help pay for half the materials. We already said we would do the labor, and he still hasn’t paid for some work The Boy did over at his house when the city threatened to fine him, so we didn’t have much hope. But still, its kind of the principle of the thing.

Anyway, while we were working on the fence, weird neighbor guy’s ex(?) wife ran through the back yard and jumped on a chair to climb through the back window into the house. It was so unexpected and strange that I think she was really surprised to see us standing there. That’s the chair on the left. On the right is the pack of feral kitties staring as we worked. I can’t even begin to explain how much cat poop is all over our yard. Ungodly amounts of cat crap.

So anyways, it gets super dark very early now, so we had to postpone putting up the rest of the boards till the next day…

…and on the next day it was all about screwing fence boards up. It took a long time and was not exciting.

But then it was done! Check out the after compared to the before. NO MORE METAL RODS. It stands up all by itself! It’s a fencing miracle.

I am amazed by how satisfying it is just to have an upright fence. Not even an awesome horizontal slat fence, just solid, upright and private fence.

Oh yeah, we gave ourselves the nice side since we paid for it all, did all the labor and were covered in cat shit for our troubles.

It only cost about $200 to do the full repair and took two days. Not bad, if I do say so.

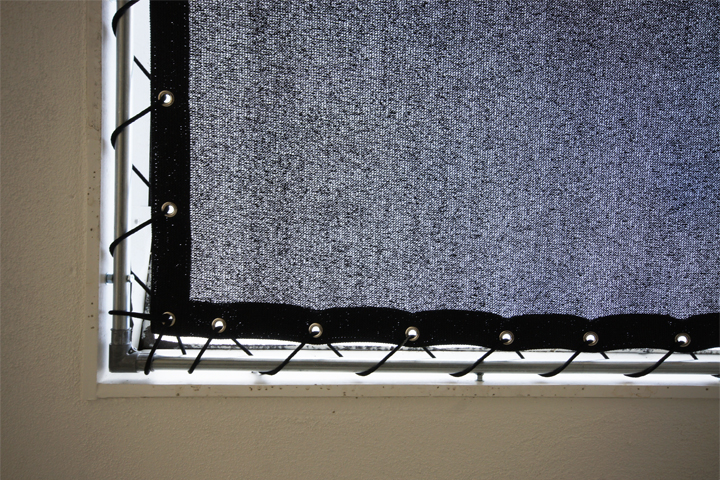

Now the perfect and professional shade sail doesn’t look so out of place next to our crappy wonky fence. I’m not sure if I want to finish the weathered boards. We were discussing some sort of opaque stain, but I think I kind of like it all aged and beat up. Something to think about for sure.

Solid as a rock. Straight as an arrow. Something something total cliche.